Solved: Lawn Mower Pull Cord Not Catching

It’s a usual Monday morning with the hassle and everything. You overslept and are now running exceptionally late for work. So, you skip breakfast and sprint towards your car. Unfortunately, just as you are about to start the car, you realize that you have forgotten your car keys back home. This further adds to the frustration. Without a car key, there is practically nothing you can do to start a vehicle unless, of course, you want to jumpstart your own car.

Like every car or vehicle needs a key to start, a push lawnmower has a similar functioning. Instead of a key, a lawn has a pull cord that needs to be pulled for the machine to start. But at times, you can find your lawn mower pull cord not catching. This can be a problem as with the lawnmower pull cord not catching; your machine is as good as dead. But this is quite a typical scenario, especially if your machine isn’t prone to active use. Therefore, this article will walk you through why your lawnmower cord won’t pull, followed by a few probable solutions for the same.

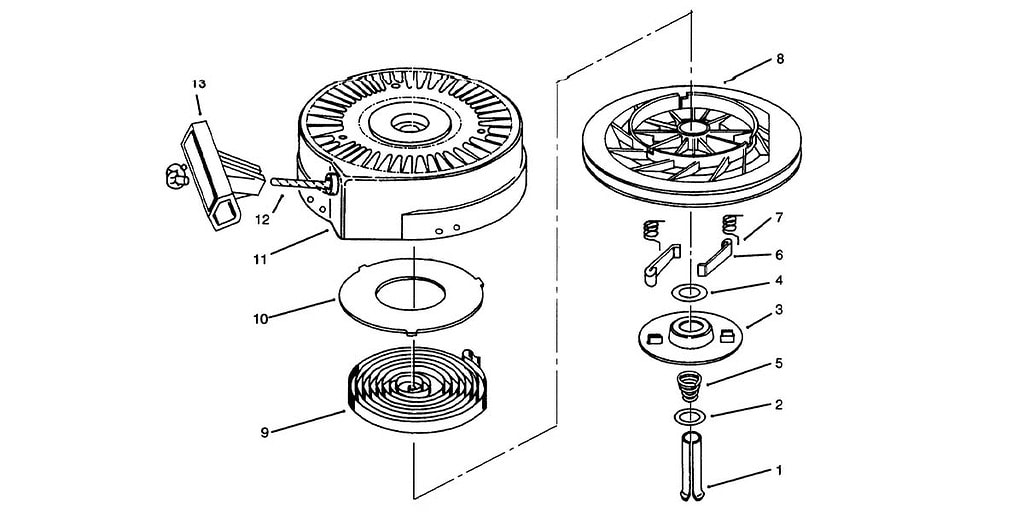

Pull Assembly Parts And Their Respective Function

If you think a pull cord is just a cord that works to run the mower, you couldn’t be more wrong. This is because a pull assembly comprises different parts that perform complex functions to keep your mower up and running. Therefore, to get a better in-depth into a problem, it is vital to know the pull assembly parts and their respective function.

1. Pull Cord

The pull cord is perhaps the most vital assembly part and the likeliest component that fails. The pull cord is wrapped around the pulley within which there is the pull assembly housing. This cord, referred to as the rope, is coiled onto the pulley under tension from the rewind spring.

2. The Pull Cord Handle

As the name suggests, the pull cord handle is required to start the engine. However, the handle can become loose due to constant usage and often tends to fly off when starting the lawnmower. Without the handle, you probably won’t be able to pull the cord with your bare hands.

3. Pulley

The pulley is central to the whole mechanism of the lawn mower’s operation mechanism. Without the pulley, there is no mower, to be exact. The pulley performs several complex functions such as guiding, feeding, storing the pull cord, retaining the coil spring, and housing the pawls. Unfortunately, since the pulley is made of plastic, it is likely to wear out over time.

4. Pulley Coil Spring

The spring is what retracts the lawnmower cord once you have pulled it. The pulley coil spring sits at the center of the pulley anchored against the pull assembly housing. So, if you find your lawnmower cord not pulling, there is possibly an issue with the pulley coil spring.

5. The Pulley Cover

The pulley cover houses the pulley and guides the pawls in and out. Also, the pulley cover is responsible for getting the pulley axle in place. Like the pulley handle, the pulley cover is made of plastic and subject to immense wear and tear.

6. The Pawls

The pawls are critical for the mower to function once the cord is pulled. These pawls fly outwards towards the centrifugal force, which is caused once the pull cord is pulled. When these pawls fly out, they latch onto the flywheel receiver, causing them to the couple. All this operation combined together causes your mower to start.

7. Flywheel Receiver

The flywheel receiver is another critical component required for the lawnmower to function. As the name suggests, the flywheel receiver is attached to the flywheel. Once the cord is pulled, the pawls latch onto the flywheel receiver and cause the engine to start. Every time the pawls contact the receiver, they couple and crank over the engine. A misfunctioning flywheel receiver could be the reason why your lawnmower may keep dying.

8. Pull Start Assembly Housing

As the name suggests, the pull start assembly housing is the outer cover that retains the various pull-start components… The housing is typically made out of plastic and doesn’t wear out that often. However, if there are any issues with either pull assembly part, you will need to remove the pull start assembly housing altogether.

Causes And Solutions To Why Your Lawn Mower Cord Won’t Pull

As we mentioned at the start of the article, the lawnmower undergoes a whole set of complex processors when you pull the cord to start the mower. Multiple parts are involved that all work in tandem to get the mower moving. However, a failure in either of the parts will cause your entire mower to malfunction. Although most of the mower is made up of plastic, only a few of them are prone to failure. Therefore, here are some possible causes and solutions to why your lawn mower won’t pull.

1. Damaged Pawls

The pawls are critical for the mower to function once the cord is pulled. These pawls fly outwards towards the centrifugal force, which is caused once the pull cord is pulled. When these pawls fly out, they latch onto the flywheel receiver, causing them to couple.

All this operation combined together causes your mower to start. But if you find your lawnmower cord not pulling, there probably is an issue with the pawls. Since these pawls are made of plastic, they are prone to wear and tear, which is probably why your engine won’t turn on.

The best way to check if the pawls are damaged or not is to remove the starter and pull the cord. This will pull out the crawls. However, if they don’t pull out, then they are DAMAGED. To remove or repair damaged pawls, trace the given steps.

1. Unplug the spark wire

2. Disassemble the housing

3. This will expose the pull cord assembly

4. Now, remove the center bolt and cap

5. Slowly pull the pawls out

6. Next, inspect the pawls for damage or other wear and tear

7. If the pawls are damaged, you will need to replace them with new ones

8. To do so, simply insert the new pawls

9. Reinstall the center bolt and cap

10. Reassemble the housing

11. Plugin the spark wire

12. Try to start the engine

Replacing damaged cords with new ones will probably start the engine. However, if you still find your lawnmower cord not pulling, then the problem could lie elsewhere.

2. Damaged Pulley

The pulley is central to the whole operation. The pulley performs several complex functions such as guiding, feeding, storing the pull cord, retaining the coil spring, and housing the pawls. Since the pulley is made out of plastic, it is likely to wear out over time. A damaged pulley will only interfere with the cord pulling around the pulley. If the cord and the pulley are jammed, then the cord won’t pull, in turn, not allowing the machine to start.

To tackle this issue, trace the given steps

1. Disconnect the spark wire

2. Pull the cord out completely

3. Now, insert a screwdriver to secure the recoil

4. Remove the cord

5. Release the screwdriver

6. Remove the center bolt

7. Remove the friction plate

8. Now, insert the new pulley

9. Ensure you align it with the housing post

10. Now, rotate the pulley to tighten the spring

11. Insert the screwdriver to hold the pulley in place

12. Keep the screwdriver in place and reattach the cord

13. Slowly release the screwdriver

14. Let the rope wind up slowly

15. Place the start back into the engine

16. Connect the spark wire

17. Try to start the engine

3. Other Probable Causes As To Why Your Lawn Mower Cord Won’t Pull

Damaged pawls and a worn-out pulley are two of the most common causes as to why your lawnmower cord won’t pull. However, there can be other probable causes that can tamper with your mower’s functioning. The thing to understand here is every manufacturer tends to do things differently, which means. However, all the mowers will have the same parts; their assembly depends on the manufacturer.

The majority of the parts in a lawnmower are made out of plastic. These plastic parts are common to wear and tear and will give out quickly once damaged. When you set out to buy a new mower, you will find that the majority of the manufacturers opt for plastic parts instead of metal to save on costs and maintain competitive pricing. In addition to the pawls and the pulley, the flywheel receiver too can give out at times.

Conclusion

A mower failure doesn’t necessarily mean you have to spend considerable bucks on repairs. Once you are familiar with the different parts and their functioning, it becomes relatively easier to detect where the problem lies. Plus, if you are handy with mechanical parts, you can quickly fix the issue yourself. You need to know the brand, model, starter, recoil, and flywheel assembly. But if you aren’t sure about your skills with mechanical parts, it is always best to have an expert come in and take a look at the machine.